Titanium Conductor Band

① Pipeline internal wall corrosion protection

② Underground storage tanks, surface storage tanks, water storage tanks

③ Condensate tanks, heat exchangers, water treatment equipment

④ Corrosion protection for ships, roads, bridges, and building steel structures, etc.

⑤ Continuous horizontal ground bed, discontinuous horizontal ground bed, shallow buried vertical ground bed

- Product Description

Product Overview

The Titanium Conductor Band for Cathodic Protection is a high-strength, corrosion-resistant titanium strip designed specifically for Impressed Current Cathodic Protection (ICCP) applications. It serves as a stable, long-life electrical pathway connecting MMO-coated anodes, platinized titanium anodes, and other impressed-current anode systems.

Engineered from ASTM B265 Grade 1 or Grade 2 titanium, this conductor band maintains exceptional conductivity and durability in harsh marine, coastal, underground, and industrial electrolytic environments. It is widely used in pipelines, offshore platforms, steel structures, and reinforced concrete protection projects.

|  |  |

Key Features

Outstanding Corrosion Resistance

Titanium delivers unmatched resistance against seawater, chlorides, soil environments, and industrial chemicals.

Stable Current Transmission

Ensures low resistance, reliable conduction, and minimized power loss in ICCP systems.

High Structural Strength

Maintains mechanical integrity under long-term load, vibration, soil stress, and marine exposure.

Long Operating Life

Titanium’s natural oxide film ensures decades of operation with minimal maintenance.

Flexible Customization

Available in coils, strips, or custom cut lengths tailored to project requirements.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Titanium Grade 1 / Grade 2 (ASTM B265) |

| Purity | Gr1 ≥ 99.6% Ti / Gr2 ≥ 99.2% Ti |

| Thickness | 0.5–5 mm (customizable) |

| Width | 10–200 mm |

| Length | Per customer specification |

| Surface Condition | Pickled / polished / matte |

| Electrical Performance | Optimized for ICCP current conduction |

| Working Environment | Seawater, soil, concrete, chemical solutions |

| Form | Strip / band / coil |

Primary Applications in Cathodic Protection

Marine & Offshore

- Offshore oil & gas platforms

- Subsea pipelines

- Ship hulls

- Seawater intake systems

Underground & Onshore Structures

- Buried pipelines (oil, gas, water)

- Aboveground storage tanks (ASTs)

- Tank bottom CP systems

- Steel pilings & jetties

Reinforced Concrete

- Bridges and viaducts

- Parking structures

- Marine concrete piles

- Coastal buildings and ports

Be used in a wide range of industries.

Water treatment

Cathodic protection of oil tank bottom plate

Aluminum foil manufacturing industry

Copper foil manufacturing industry

Energy industry

Chemical industry

Medical equipment

Electronic plating

Marine engineering

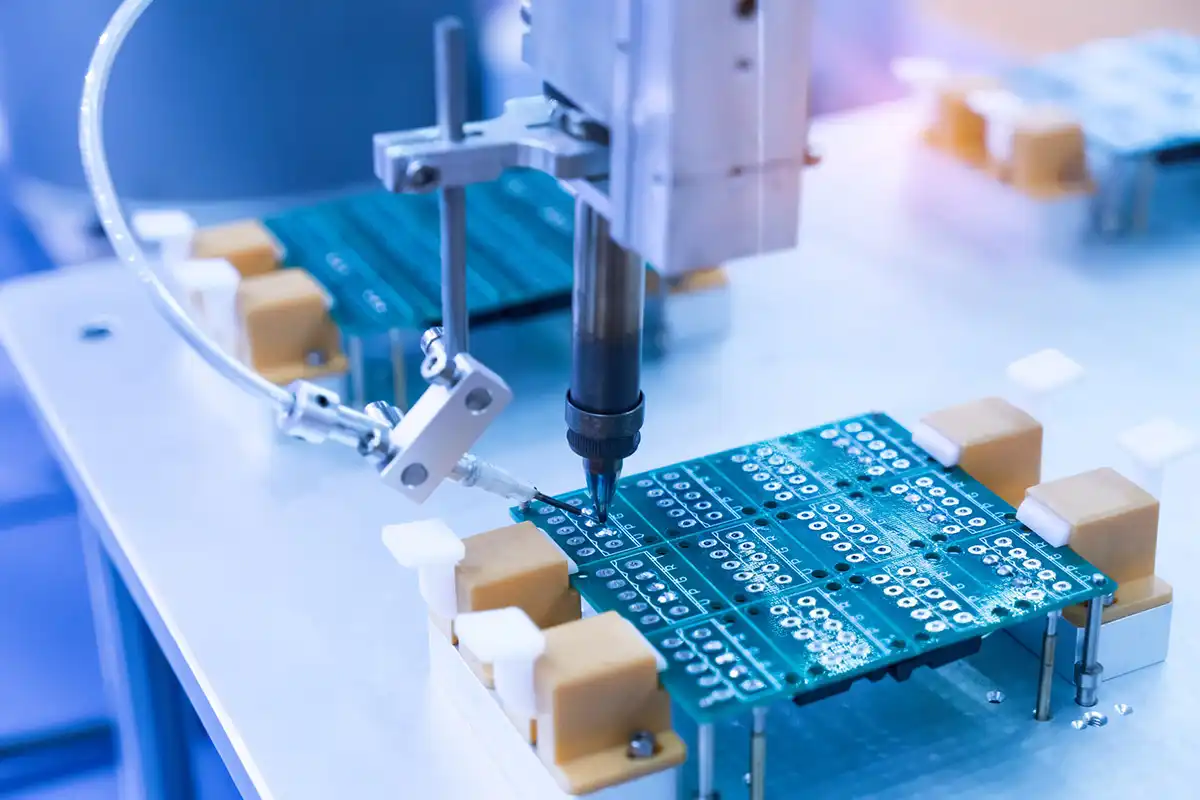

Our Workshop

Benefits for ICCP System Performance

- Enhances continuity and stability of current distribution

- Improves energy efficiency of rectifier output

- Prevents premature failure of anodes caused by poor conductivity

- Extends the service life of the entire CP system

- Reduces maintenance costs for long-term asset protection

Manufacturing & Quality Assurance

- High-purity titanium sourced from certified suppliers

- Precision rolling, slitting, and annealing for dimensional accuracy

- Mechanical strength and conductivity testing for every batch

- Corrosion simulation tests for seawater and soil conditions

- Professional packaging for global transport of long and thin titanium strips

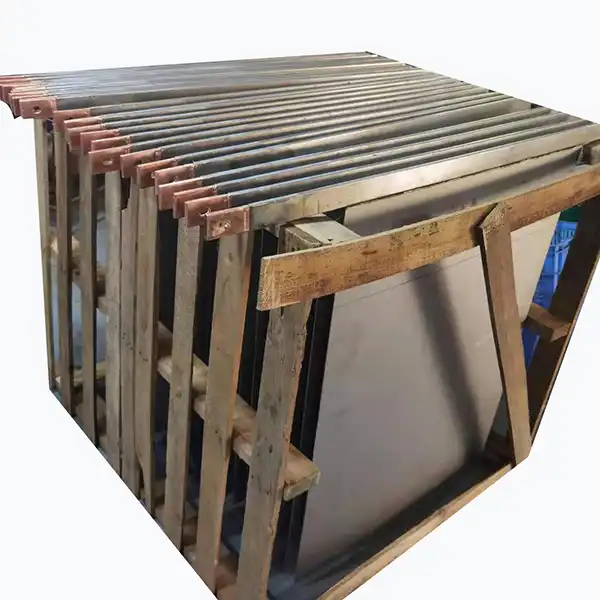

Package

Standard Export Packaging

Each titanium conductor band is protected with anti-scratch film and wrapped in moisture-proof plastic to prevent oxidation and surface damage.

Customized Packing Options

Tailored packaging such as reinforced wooden cases, palletized bundles, or individual carton packing is available based on customer requirements.

Shock-proof & Moisture-proof Protection

Multi-layer cushioning and sealed wrapping ensure safe delivery during long-distance sea or air transportation.

Labeling & Identification

Each package includes clear labels with product grade, dimensions, batch number, heat number, and inspection status for easy traceability.

Safe Loading & Fast Delivery

Products are palletized and securely strapped to avoid movement during shipping. We support EXW, FOB, CIF, and DDP terms.

International Shipping Support

Air freight, sea freight, express delivery (DHL/UPS/FedEx) all available with export documentation including packing list, invoice, CO, and test reports.

|  |  |

Our Certificates

Our Team

|  |

Get a Quote

For cathodic protection engineering drawings, custom dimensions, or bulk project requirements, contact our technical team. We offer tailored solutions for pipelines, offshore structures, and concrete protection systems.

For more data about our Titanium Conductor Band or to examine your particular requirements, if it's not too much trouble, reach us at info@di-nol.com.