The Advantages of Using Titanium Electrodes in Electroplating Processes

Electroplating is a crucial process in various industries, from automotive manufacturing to jewelry production. As technology advances, so do the materials and techniques used in electroplating. One such advancement is the use of titanium electrodes, which have revolutionized the electroplating industry. In this article, we'll explore the numerous advantages of using electroplating titanium electrodes and why they're becoming increasingly popular in modern electroplating processes.

Grasping Titanium Electrodes in Electroplating

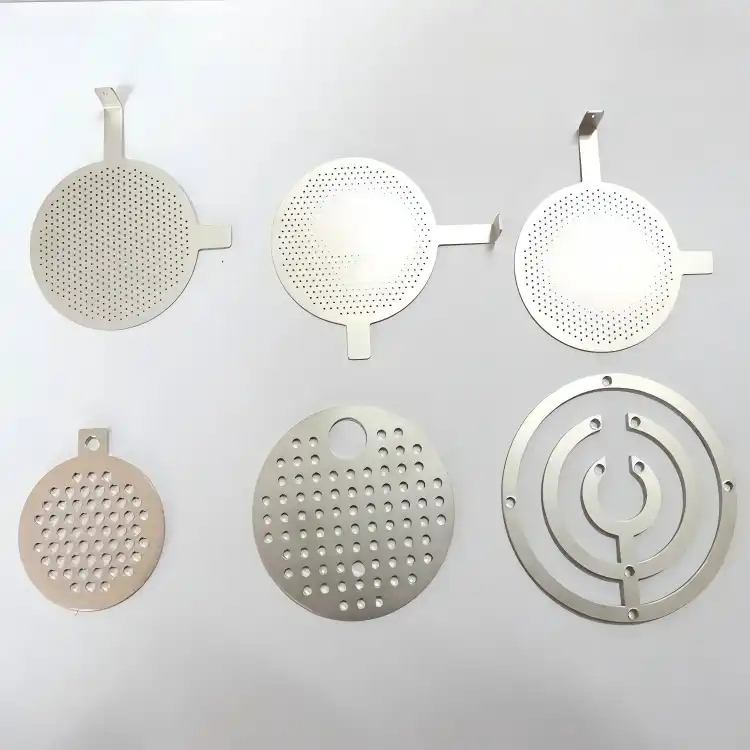

Titanium electrodes have emerged as a game-changer in the electroplating industry. These electrodes are crafted from high-purity titanium and often coated with precious metals or metal oxides to enhance their performance. The use of titanium as a base material offers a unique combination of properties that make it ideal for electroplating applications.

An electroplating titanium electrode typically consists of a titanium substrate coated with a thin layer of noble metals or metal oxides. This coating is crucial as it provides the necessary catalytic activity for the electroplating process while the titanium substrate offers excellent mechanical and chemical stability.

The popularity of titanium electrodes in electroplating can be attributed to their superior properties compared to traditional electrode materials. These properties include exceptional corrosion resistance, high mechanical strength, and excellent conductivity when properly coated. These characteristics make titanium electrodes a versatile and reliable choice for a wide range of electroplating applications.

Key Benefits of Titanium Electrodes in Electroplating

The use of electroplating titanium electrodes offers numerous advantages over conventional electrode materials. Let's delve into some of the key benefits:

- Corrosion Resistance: One of the most significant advantages of titanium electrodes is their outstanding corrosion resistance. Titanium naturally forms a protective oxide layer when exposed to oxygen, making it highly resistant to corrosion in even the most aggressive electrolytes. This property ensures that titanium electrodes maintain their integrity and performance over extended periods, even in harsh electroplating environments.

- Longevity and Durability: The exceptional corrosion resistance of titanium electrodes translates directly into increased longevity. These electrodes can withstand repeated use in various electrolyte solutions without significant degradation. This durability not only reduces the frequency of electrode replacements but also ensures consistent performance over time, leading to more stable and reliable electroplating processes.

- Dimensional Stability: Titanium electrodes exhibit excellent dimensional stability during the electroplating process. Unlike some other electrode materials that may warp or deform under certain conditions, titanium maintains its shape and size. This stability is crucial for achieving uniform and high-quality plating results, especially in precision applications where maintaining exact dimensions is critical.

- Versatility: Electroplating titanium electrodes are highly versatile and can be used in a wide range of electroplating applications. They are suitable for both anodic and cathodic processes and can be used with various electrolyte solutions. This versatility makes titanium electrodes a popular choice across different industries and applications, from decorative plating to functional coatings in the aerospace industry.

- Enhanced Efficiency: The use of titanium electrodes can significantly improve the efficiency of electroplating processes. Their excellent conductivity, when properly coated, ensures efficient current distribution across the electrode surface. This uniform current distribution leads to more even plating and can reduce the overall energy consumption of the electroplating process.

- Cost-Effectiveness: While the initial cost of titanium electrodes may be higher than some traditional materials, their long-term cost-effectiveness is undeniable. The extended lifespan of these electrodes, coupled with their consistent performance, results in reduced maintenance costs and fewer production interruptions. Over time, this can lead to significant cost savings for electroplating operations.

- Environmental Benefits: The durability and efficiency of titanium electrodes contribute to their environmental friendliness. By reducing the frequency of electrode replacements, titanium electrodes help minimize waste generation. Additionally, their ability to operate efficiently can lead to reduced energy consumption in electroplating processes, aligning with sustainability goals in modern manufacturing.

Applications and Future Prospects of Titanium Electrodes in Electroplating

The advantages of electroplating titanium electrodes have led to their widespread adoption across various industries. Some key applications include:

- Precious Metal Plating: Titanium electrodes are extensively used in the electroplating of precious metals like gold, silver, and platinum. Their stability and inert nature make them ideal for these high-value applications, ensuring minimal contamination and high-quality plating results.

- Hard Chrome Plating: In the automotive and aerospace industries, titanium electrodes are increasingly used for hard chrome plating applications. Their durability and resistance to the harsh conditions of chrome plating baths make them an excellent choice for these demanding applications.

- Printed Circuit Board Manufacturing: The electronics industry benefits from the precision and reliability of titanium electrodes in the production of printed circuit boards. The dimensional stability of these electrodes is particularly valuable in this application, where maintaining exact specifications is crucial.

- Wastewater Treatment: Beyond traditional electroplating, titanium electrodes are also finding applications in electrochemical wastewater treatment processes. Their corrosion resistance and long lifespan make them ideal for these environmentally critical applications.

Looking to the future, the role of electroplating titanium electrodes is expected to grow even further. As industries continue to seek more efficient, durable, and environmentally friendly solutions, titanium electrodes are well-positioned to meet these evolving needs. Ongoing research and development in coating technologies for titanium electrodes promise to further enhance their performance and expand their applications.

Innovations in nanotechnology and advanced materials science are opening up new possibilities for titanium electrode design. These advancements could lead to even more efficient electrodes with tailored properties for specific electroplating applications. Additionally, as industries push towards more sustainable practices, the long-lasting nature of titanium electrodes aligns well with goals of reducing waste and improving resource efficiency.

The integration of titanium electrodes with smart manufacturing technologies is another exciting prospect. The development of sensor-equipped electrodes could provide real-time data on plating processes, allowing for unprecedented levels of control and optimization in electroplating operations.

Conclusion

The advantages of using titanium electrodes in electroplating processes are clear and multifaceted. From their exceptional corrosion resistance and longevity to their versatility and efficiency, these electrodes offer significant benefits over traditional materials. As industries continue to evolve and demand higher performance and sustainability, the role of electroplating titanium electrodes is set to become even more prominent.

To learn more about how electroplating titanium electrodes can benefit your operations or to explore custom solutions, don't hesitate to reach out to the experts. Contact Shaanxi Tianyi at info@di-nol.com for more information on their advanced electrochemical electrode materials and tailored electroplating solutions.

References

1. Walsh, F. C., & Ponce de León, C. (2018). Versatile electrochemical coatings and surface layers from aqueous methanesulfonic acid. Surface and Coatings Technology, 347, 511-528.

2. Martínez-Huitle, C. A., & Ferro, S. (2006). Electrochemical oxidation of organic pollutants for the wastewater treatment: direct and indirect processes. Chemical Society Reviews, 35(12), 1324-1340.

3. Aromaa, J., & Forsén, O. (2006). Evaluation of the electrochemical activity of a Ti–RuO2–TiO2 permanent anode. Electrochimica Acta, 51(27), 6104-6110.

4. Chen, X., Chen, G., & Yue, P. L. (2001). Stable Ti/IrOx-Sb2O5-SnO2 anode for O2 evolution with high oxygen evolution potential. The Journal of Physical Chemistry B, 105(20), 4623-4628.

5. Kraft, A. (2007). Doped diamond: a compact review on a new, versatile electrode material. International Journal of Electrochemical Science, 2(5), 355-385.