The Science Behind Electrolytic Sodium Hypochlorite Generation

Electrolytic sodium hypochlorite generators utilize an interesting electrochemical prepare to create a effective disinfectant arrangement on-site. At the heart of these frameworks lies a basic however brilliant concept: the electrolysis of salt water. When an electric current passes through a brine arrangement, it triggers an arrangement of chemical responses that result in the arrangement of sodium hypochlorite.

The prepare starts with conventional salt (sodium chloride) broken up in water. As power streams through the arrangement, it causes the sodium and chloride particles to partitioned. The chloride particles are at that point oxidized at the anode, shaping chlorine gas. At the same time, at the cathode, water particles are decreased to frame hydrogen gas and hydroxide particles. These components rapidly recombine in the arrangement to create sodium hypochlorite – the dynamic cleaning specialist.

What sets electrolytic sodium hypochlorite generators apart is their ability to produce this disinfectant on-demand and in precise concentrations. This eliminates the need for transportation and storage of hazardous chemicals, significantly reducing safety risks and environmental concerns associated with traditional chlorination methods.

The coming about sodium hypochlorite arrangement is exceedingly compelling against a wide extent of pathogens, counting microscopic organisms, infections, and protozoa. Its power, combined with its generally secure taking care of characteristics, makes it a perfect choice for water treatment applications over different scales—from little community frameworks to expansive metropolitan water supplies.

Advantages of Electrolytic Sodium Hypochlorite Generators in Water Treatment

The adoption of electrolytic sodium hypochlorite generators offers numerous benefits that address many of the challenges associated with conventional water chlorination methods. These advantages contribute to safer, more sustainable, and cost-effective water treatment solutions.

- Improved Security: One of the most critical benefits of utilizing electrolytic sodium hypochlorite generators is the made strides security profile. By creating the disinfectant on-site, these frameworks dispose of the requirement to transport and store expansive amounts of unsafe chlorine gas or concentrated fade arrangements. This essentially decreases the chance of mishaps, spills, or introduction to destructive chemicals, making a more secure environment for both specialists and adjacent communities.

- Steady Cleansing: Electrolytic generators give a relentless and solid supply of sodium hypochlorite at steady concentrations. This guarantees uniform sanitization all through the water treatment handle, lessening the hazard of beneath- or over-chlorination. The capacity to fine-tune the chlorine yield also permits more exact control over sanitization levels, adjusting to shifting water quality conditions and request changes.

- Cost-Effectiveness: Whereas the beginning venture in an electrolytic sodium hypochlorite generator may be higher than conventional chlorination strategies, the long-term operational costs are regularly altogether lower. These frameworks require as it were salt, water, and power to create the disinfectant, dispensing with the continuous costs related with obtaining, transporting, and putting away chlorine items. Furthermore, the decreased require for specialized dealing with hardware and security measures contributes to generally fetched reserve funds.

- Environmental Benefits: Electrolytic sodium hypochlorite generation is an environmentally friendly alternative to conventional chlorination methods. By producing the disinfectant on-site, it reduces the carbon footprint associated with transportation and packaging of chlorine products. Furthermore, the process does not introduce any new chemicals into the environment, as it simply converts salt and water into a disinfectant solution.

- Scalability and Flexibility: These generators can be scaled to meet the needs of various applications, from small-scale systems for swimming pools or hotels to large municipal water treatment plants. Their modular design allows for easy expansion or downsizing as demand changes. This flexibility makes them suitable for a wide range of industries and settings, including remote locations where regular chemical deliveries may be challenging.

- Improved Taste and Odor: Sodium hypochlorite produced through electrolysis typically results in better-tasting and less odorous water compared to other chlorination methods. This is partly due to the absence of chemical stabilizers and additives often found in commercial bleach products. The ability to generate fresh disinfectant on-demand also helps maintain optimal chlorine levels, reducing the formation of unpleasant chlorine by-products.

Implementation Challenges and Future Prospects

While electrolytic sodium hypochlorite generators offer numerous advantages, their implementation is not without challenges. Understanding these hurdles and the future outlook for this technology is crucial for organizations considering adoption.

- Starting Speculation: The forthright fetched of introducing an electrolytic sodium hypochlorite generator can be considerable, especially for littler operations or regions with restricted budgets. This introductory speculation incorporates not as it were the generator itself but moreover related hardware such as brine tanks, control frameworks, and conceivably office adjustments. Be that as it may, it's vital to consider this fetched in the setting of long-term investment funds on chemical buys, transportation, and capacity.

- Technical Expertise: Operating and maintaining electrolytic generators requires specialized knowledge and skills. Water treatment operators need training to understand the electrochemical process, monitor system performance, and troubleshoot issues. This may necessitate additional staff training or the hiring of personnel with specific expertise. However, many manufacturers offer comprehensive training programs and ongoing support to facilitate smooth implementation and operation.

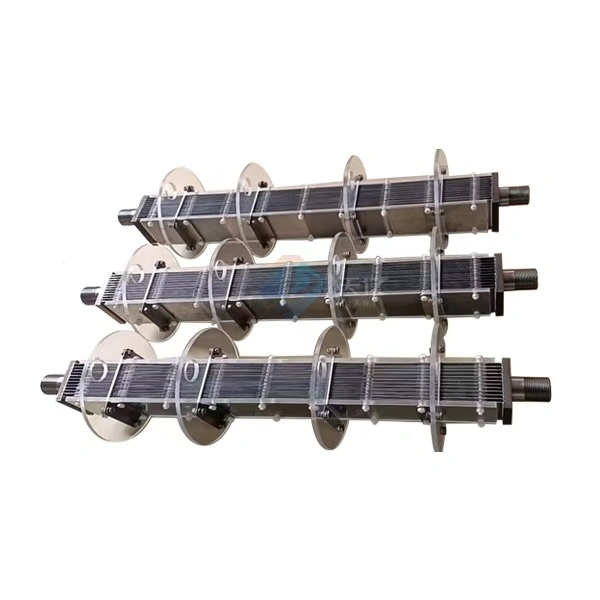

- Water Quality Considerations: The efficiency of electrolytic sodium hypochlorite generation can be affected by the quality of the input water. High levels of hardness or certain minerals can impact the electrolysis process or lead to scale buildup on electrodes. In some cases, pre-treatment of the input water may be necessary to ensure optimal generator performance and longevity. This underscores the importance of thorough water analysis and system design before implementation.

- Energy Consumption: Electrolytic generators require a constant supply of electricity to operate, which may be a concern in areas with high energy costs or unreliable power supplies. However, advancements in electrode technology and system efficiency continue to reduce energy requirements. Additionally, the potential for integration with renewable energy sources offers exciting possibilities for sustainable operation.

Looking to the future, the prospects for electrolytic sodium hypochlorite generators are promising. Ongoing research and development are focusing on several key areas:

- Improved Electrode Materials: Scientists are exploring new materials and coatings for electrodes to enhance durability, efficiency, and resistance to scaling. These advancements could lead to longer-lasting systems with reduced maintenance requirements and lower operating costs.

- Smart Control Systems: Integration of artificial intelligence and IoT (Internet of Things) technologies is enabling more sophisticated control and monitoring of electrolytic generators. These smart systems can optimize chlorine production based on real-time water quality data, predict maintenance needs, and even integrate with broader water management systems for comprehensive treatment solutions.

- Miniaturization: Efforts are underway to develop smaller, more compact electrolytic generators suitable for point-of-use applications. This could expand the technology's reach to individual households, small businesses, or emergency response situations where portable, on-demand disinfection is crucial.

- Hybrid Systems: Researchers are exploring ways to combine electrolytic generators with other water treatment technologies, such as UV disinfection or advanced oxidation processes. These hybrid systems could offer more comprehensive water treatment solutions, addressing a wider range of contaminants while maintaining the benefits of on-site disinfectant production.

Conclusion

Electrolytic sodium hypochlorite generators represent a significant advancement in water chlorination technology. By offering enhanced safety, consistent disinfection, cost-effectiveness, and environmental benefits, these systems are becoming essential tools in the quest for safe and sustainable water treatment solutions. As the technology continues to evolve and improve, its adoption across various sectors is likely to accelerate, contributing to better water quality and public health outcomes worldwide.

For those interested in learning more about electrolytic sodium hypochlorite generators and their potential applications, we invite you to reach out to our team of experts. Contact us at info@di-nol.com for personalized guidance on implementing this innovative technology in your water treatment processes.