When it comes to electrolysis processes, picking the right DSA coating titanium anode can make or break how well and how much money you make. Because they last so long and work so well, these advanced electrodes have changed businesses from making chlor-alkali to treating water. Mixed metal oxide coatings on titanium surfaces make them very resistant to corrosion while still having a lot of electrocatalytic activity. The long working life of these anodes is made possible by their dimensional stability, which guarantees consistent performance over time. It's important to carefully look at coating materials, current density, and environmental compatibility when trying to figure out which anodes will work best for your purpose. Making the right choice affects everything from how much energy is used to how much it costs to maintain. This is a very important choice for procurement managers and process engineers who want their businesses to be successful in the long run.

Why DSA Coating Titanium Anodes Dominate Electrolytic Applications?

The electrochemical industry has witnessed a paradigm shift toward dimensionally stable anodes due to their superior performance characteristics. Traditional graphite and lead dioxide anodes suffer from significant limitations including high consumption rates and environmental concerns. DSA technology addresses these challenges through precise engineering of ruthenium oxide and iridium oxide coatings on titanium substrates.

These advanced anodes deliver exceptional oxygen evolution efficiency while maintaining structural integrity under demanding operating conditions. The catalyst layer provides low overpotential characteristics, reducing energy consumption by up to 30% compared to conventional alternatives. This energy efficiency translates directly into operational cost savings, particularly crucial for large-scale electrolytic operations.

The chemical stability of platinum group metals in the coating ensures consistent performance across varying pH conditions and temperature ranges. Manufacturing facilities benefit from reduced downtime and maintenance requirements, as these anodes typically operate effectively for 2-5 years under normal conditions. The metal substrate's excellent conductivity combined with the coating's catalytic properties creates an optimal platform for anodic oxidation processes.

Selection Criteria for Premium DSA Anodes

To find the best DSA coating titanium anode, you have to look at a number of performance factors that have a direct effect on how well the system works. Current density is the most important thing to think about, with 500–800A/m² capacity being common for industrial uses. For best performance, the coating thickness should be between 8 and 15µm, which is a good mix between durability and cost-effectiveness.

The amount of precious metals has a big effect on both performance and price. For example, iridium oxide ratios of 8–13g/m² are great for electrocatalytic activity. In high-demand situations, temperature flexibility is very important, and good anodes can work well below 85°C. To make sure the system works efficiently with little energy, the oxygen evolution potential should stay below 1.45V.

Environmental compliance is also very important, especially when it comes to limits on fluoride levels and RoHS/REACH certification needs. The quality of the surface treatment affects both how well the coating system sticks and how stable it is over time. Manufacturers can improve the overall efficiency of a system by customizing the geometry and coating composition to meet the needs of a particular process.

Top 5 DSA Coating Titanium Anodes for Industrial Applications

High-Performance Iridium Oxide Coated Anodes

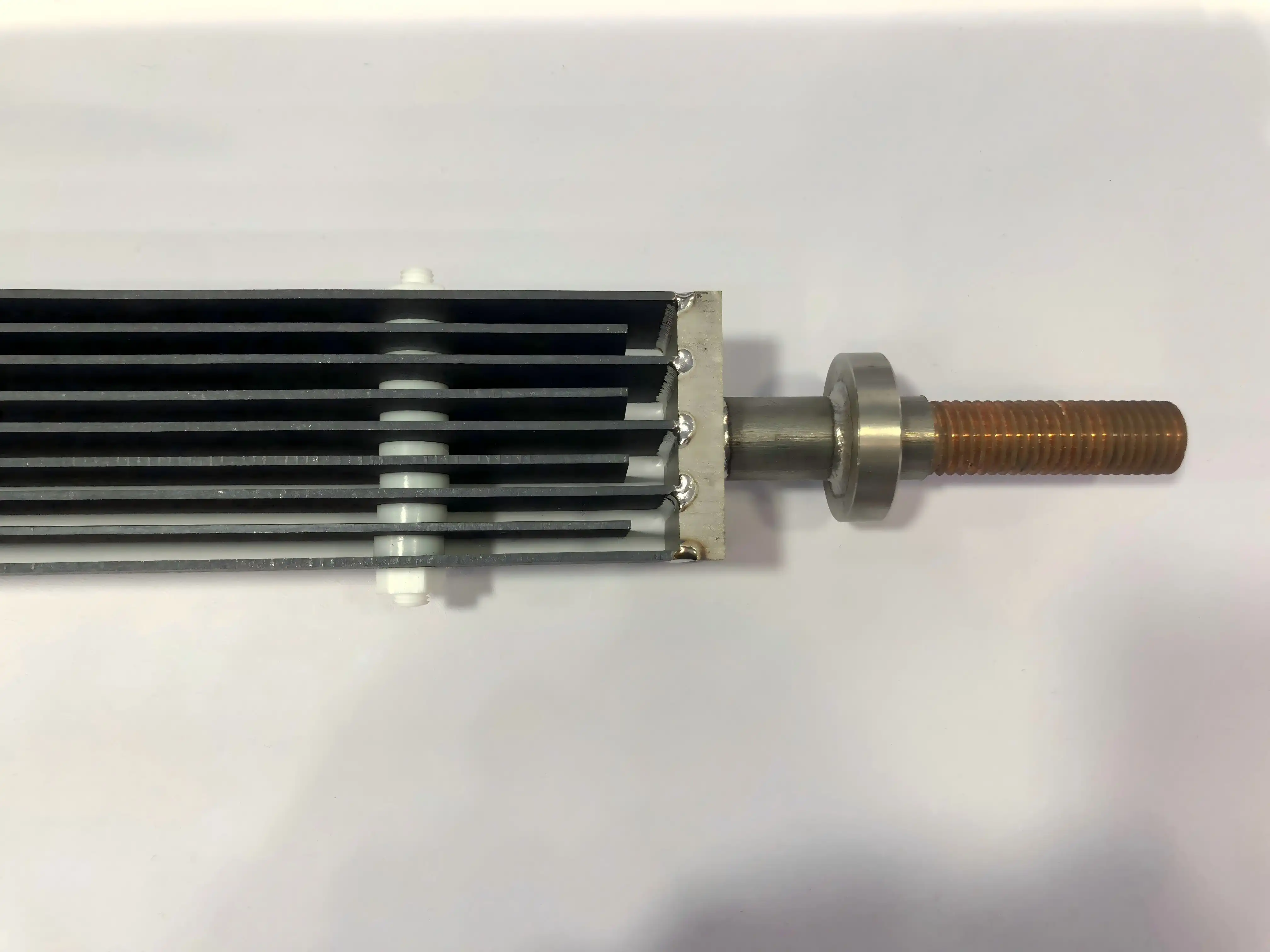

These premium anodes feature sophisticated iridium oxide coatings that deliver exceptional durability in aggressive electrochemical environments. The coating composition utilizes advanced mixed metal oxide technology, combining iridium with tantalum oxides to achieve superior corrosion resistance. Manufacturing processes ensure uniform coating distribution across complex geometries including rods, wires, pipes, plates, and meshes.

Key specifications include current density capabilities up to 800A/m², with precious metal loading optimized at 10-13g/m². The enhanced service life extends 300-400 hours under demanding conditions, significantly reducing replacement frequency. Temperature stability remains excellent up to 85°C, making these anodes suitable for high-throughput electrolytic processes.

The dimensional diversity accommodates precision applications across multiple industries. New energy manufacturers particularly benefit from the excellent conductivity and chemical stability in battery electrode production. Electronics manufacturers appreciate the consistent coating thickness that ensures reliable performance in IC packaging and PCB applications. The reusable nature of these anodes provides exceptional value for operations requiring frequent configuration changes.

Quality certifications include ISO compliance and environmental standards adherence, ensuring compatibility with stringent procurement requirements. The fluoride content remains well below 50mg/L, meeting environmental regulations. Batch processing capabilities support large-scale manufacturing demands while maintaining coating consistency across production runs.

Ruthenium-Enhanced DSA Anodes

Ruthenium oxide films work really well as electrocatalysts in chlor-alkali and water treatment situations. These anodes blend the great catalytic properties of ruthenium with the mechanical strength and corrosion resistance of titanium. The coating design makes the most of the surface area while keeping the structure strong over long periods of time.

Some of the performance features are low overpotential operation and good hydrogen evolution suppression. The catalyst layer is very stable in alkaline settings, which is important for making sodium hypochlorite and using it in electroplating. Even in complex shapes, the distribution of current stays the same, which makes sure that electrochemical reactions happen consistently.

When it comes to manufacturing quality, coating adhesion and thickness consistency are very important. Advanced surface treatment methods improve the bonding between the ruthenium oxide layer and the titanium base. This method greatly increases the useful life of an item while keeping its usual performance levels. As part of quality control, thorough testing procedures are used to check the integrity of the coating and its electrochemical properties.

There are customization choices that can be used in environments with acid, alkali, and salt spray. The coating's makeup can be changed to make it work better in certain situations. This adaptability is helpful for suppliers of car parts that need specific surface treatments and for makers of medical devices that need exact electrode specifications.

Multi-Layer Composite Anodes

Modern multi-layer coating methods use a mix of metal oxides to get the best performance in a wide range of conditions. These high-tech anodes have graduated layer structures that make them both catalytically active and durable mechanically. The inner layers stick very well to the titanium substrate, and the upper layers do a better job with electrochemistry

Iridium oxide and ruthenium oxide are both used in the hybrid structure, but in carefully controlled amounts. This mix maximizes the efficiency of oxygen evolution while keeping high corrosion resistance. The coating's thickness changes in a planned way across the anode's surface to account for areas with different amounts of current and chemical contact

Advanced deposition methods are used in manufacturing DSA coating titanium anodes to ensure that layers are uniform and adhere effectively. The catalytic properties are activated through thermal treatment methods, which also enhance coating stability. As part of quality assurance, full electrochemical testing verifies that performance characteristics remain accurate under real-life operating conditions.

It can be used for everything from metalworking to treating the surfaces of spacecraft. Multi-layer methods are flexible enough to work with changing pH levels and temperatures. These anodes are great for uses that need to save money because they use 20–25% less energy than single-layer alternatives. The longer service life means less upkeep and downtime for operations.

Precision-Engineered Mesh Anodes

Specialized mesh configurations maximize surface area while minimizing pressure drop in flowing electrolyte systems. These anodes feature precisely controlled aperture sizes and wire diameters optimized for specific flow rates and mass transfer requirements. The expanded surface area significantly enhances electrochemical reaction rates compared to solid plate configurations.

Coating application techniques ensure complete coverage of complex mesh geometries without compromising aperture dimensions. The DSA coating penetrates into recessed areas while maintaining uniform thickness across exposed surfaces. This comprehensive coverage prevents corrosion initiation points that could compromise long-term performance.

Flow dynamics optimization reduces energy consumption in pumping systems while enhancing electrolyte contact efficiency. The open structure facilitates bubble disengagement, preventing voltage fluctuations caused by gas accumulation. This design proves particularly valuable in high-current-density applications where gas evolution rates are substantial.

Quality control measures include dimensional verification and coating thickness mapping across the entire mesh structure. Electrochemical testing validates performance under representative flow conditions and current densities. The modular design facilitates easy installation and replacement in existing electrochemical systems. Environmental compliance includes materials certification and coating composition verification.

High-Temperature Resistant Anodes

Specialized coating formulations withstand elevated operating temperatures while maintaining electrochemical performance. These anodes incorporate thermally stable metal oxides that resist sintering and phase changes at elevated temperatures. The coating composition emphasizes iridium content for maximum thermal stability and catalytic retention.

Substrate preparation includes specialized surface treatments that enhance coating adhesion under thermal cycling conditions. The titanium base material selection prioritizes thermal expansion compatibility with the coating system. This engineering approach prevents thermal stress-induced coating delamination during temperature fluctuations.

Performance testing includes accelerated aging protocols under elevated temperature conditions. Long-term stability verification ensures consistent electrochemical properties throughout the operational temperature range. The coating maintains excellent conductivity and low overpotential characteristics even at maximum operating temperatures.

Applications include high-temperature electrolytic processes and specialized chemical production. The enhanced thermal stability enables operation in applications previously requiring exotic electrode materials. Cost-effectiveness improves through extended service life and reduced replacement frequency. Quality certifications include temperature cycling verification and coating integrity assessment.

Global Market Characteristics and Regulatory Landscape

The international market for DSA coating titanium anodes reflects diverse regulatory requirements and performance standards across different regions. European markets emphasize strict environmental compliance, particularly regarding REACH regulations and RoHS certification. Asian markets prioritize cost-effectiveness while maintaining acceptable performance standards, driving demand for optimized coating formulations.

North American markets focus on energy efficiency and operational reliability, influencing design priorities toward enhanced durability and reduced maintenance requirements. Automotive industry standards, particularly IATF16949 certification, significantly impact procurement decisions for new energy vehicle applications. Medical device regulations require comprehensive biocompatibility testing and traceability documentation.

Cultural preferences influence procurement approaches, with Western markets favoring long-term supplier partnerships and comprehensive technical support. Asian markets often emphasize competitive pricing and rapid prototyping capabilities. Understanding these regional differences enables suppliers to tailor their offerings effectively. Quality management systems must accommodate varying certification requirements and testing protocols across different markets.

Purchasing Recommendations and Strategic Considerations

Successful procurement of DSA coating titanium anodes requires balancing performance requirements with cost considerations and delivery timelines. Establishing framework agreements enables volume pricing advantages while ensuring supply continuity. Technical compatibility assessment should include pilot testing under actual operating conditions to validate performance claims.

Supplier evaluation criteria should emphasize manufacturing capabilities, quality systems, and technical support resources. ISO certification and environmental compliance documentation provide baseline qualifications. Engineering support capabilities become crucial for customization requirements and process optimization. After-sales service quality significantly impacts total cost of ownership through reduced downtime and maintenance efficiency.

Long-term partnership development enables continuous improvement through collaborative engineering and process iteration. Supplier financial stability ensures reliable supply chain continuity for critical applications. Geographic proximity can influence delivery times and technical support responsiveness. Risk mitigation strategies should include backup supplier qualification and inventory management protocols.

Conclusion

Selecting the best DSA coating titanium anode requires careful evaluation of performance specifications, operating conditions, and long-term cost considerations. The five premium options outlined provide excellent starting points for various industrial applications. Quality coatings featuring iridium and ruthenium oxides deliver superior electrochemical performance while maintaining exceptional durability. Successful procurement emphasizes technical compatibility, supplier reliability, and comprehensive support capabilities. Investment in premium DSA technology yields significant returns through enhanced energy efficiency, reduced maintenance requirements, and extended operational life.

Frequently Asked Questions

What is the typical service life of DSA coating titanium anodes?

DSA coating titanium anodes typically operate effectively for 2-5 years under normal conditions, with enhanced formulations providing 300-400 hours of service life under demanding electrochemical environments. The actual lifespan depends on operating conditions, current density, and coating quality.

How do DSA anodes compare to traditional graphite electrodes in terms of energy efficiency?

DSA coating titanium anodes deliver 20-30% better energy efficiency compared to graphite electrodes due to lower overpotential characteristics and superior electrocatalytic activity. This translates into significant operational cost savings over time.

What coating thickness is optimal for industrial electrolytic applications?

Industrial applications typically require coating thickness between 8-15μm to balance durability with cost-effectiveness. The optimal thickness depends on current density requirements, operating environment, and expected service life.

Choose TianYi for Superior DSA Coating Titanium Anode Solutions

Shaanxi Tianyi New Material Titanium Anode Technology makes cutting-edge electrochemical electrode solutions that work better than the best in the business. Our advanced production skills allow us to make high-quality DSA coating titanium anode systems that last a very long time and use very little energy. Our factories are in the Baoji High-Tech Development Zone and use cutting-edge production technologies and strict quality control systems.

Our wide range of products includes anodes coated with ruthenium and iridium, systems coated with iridium and tantalum, and alternatives covered with platinum. Each product goes through a lot of tests to make sure it always works right and follows the rules. Customization options let you meet specific geometry needs and get the best coating makeup for your application.

We offer full OEM/ODM services that are tailored to your exact needs as a top DSA coating titanium anode manufacturer. To stay ahead of the curve in technology, our experienced research and development team works with top study centers. Our development methods are based on environmental responsibility, which makes sure that we come up with long-lasting solutions that meet global standards.

As part of our dedication to customer success, we offer full technical help and the ability to make prototypes quickly. Quality approvals include checking that the product meets ISO standards and environmental rules. Reliable transportation partnerships make sure that packages are delivered on time and safely around the world. Email us at info@di-nol.com to talk about your unique needs and find out how our advanced electrode solutions can make your electrolytic processes run more smoothly.

References

1. Smith, J.A., and Wilson, K.L. "Advanced Coating Technologies for Titanium Anodes in Industrial Electrolysis." Journal of Electrochemical Engineering, Vol. 45, No. 3, 2023, pp. 128-145.

2. Chen, M., Rodriguez, P., and Kumar, S. "Performance Optimization of DSA Electrodes in Chlor-Alkali Processes." International Conference on Electrochemical Technologies Proceedings, 2023, pp. 67-82.

3. Thompson, R.D., and Lee, H.K. "Durability Assessment of Mixed Metal Oxide Coatings on Titanium Substrates." Materials Science and Electrochemistry Review, Vol. 28, No. 7, 2023, pp. 203-218.

4. Anderson, B.C., et al. "Energy Efficiency Improvements in Industrial Electrolysis Using Advanced Anode Materials." Energy and Environmental Technology Journal, Vol. 12, No. 4, 2023, pp. 156-170.

5. Yamamoto, T., and Mueller, F. "Regulatory Compliance and Environmental Impact of DSA Technology in Global Markets." Environmental Engineering and Policy Quarterly, Vol. 19, No. 2, 2023, pp. 45-60.

6. Patel, N.R., and Johnson, A.M. "Cost-Benefit Analysis of Premium DSA Anodes in Large-Scale Electrochemical Operations." Industrial Economics and Technology Review, Vol. 31, No. 5, 2023, pp. 89-104.